Mechanical Pressure Gauges: Reliability at a Glance

When it comes to accurate and dependable pressure measurement, few instruments match the reliability of a mechanical pressure gauge. These rugged devices have been an integral part of countless industries, providing critical data for applications ranging from manufacturing and energy production to healthcare and HVAC systems. In this article, we'll explore the key features, advantages, and applications of mechanical manometers and why they continue to be a trusted choice in pressure measurement.

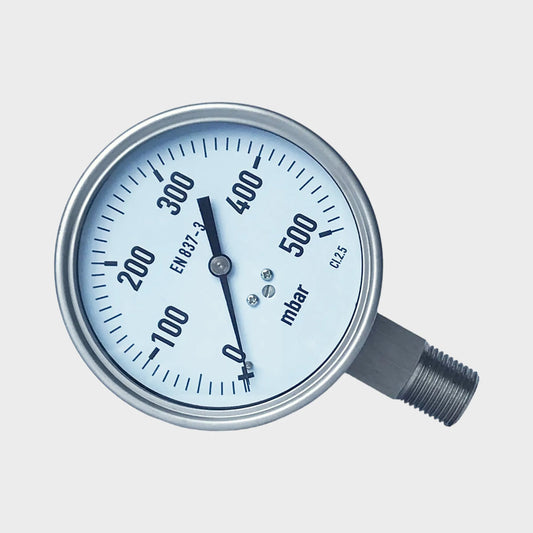

The Anatomy of a Mechanical Pressure Gauge

A mechanical pressure gauge is a marvel of engineering simplicity. It consists of a few fundamental components:

1. Bourdon Tube: At the heart of the gauge is the Bourdon tube, a curved, hollow tube that responds to pressure changes. As pressure increases or decreases, the Bourdon tube expands or contracts.

2. Linkage: The motion of the Bourdon tube is transferred to a system of linkages, levers, and gears, which ultimately moves the pointer on the gauge's dial.

3. Dial: The dial of the gauge displays pressure values in a clear and easy-to-read manner.

The Advantages of Mechanical Pressure Gauges

1. Accuracy: Pointer pressure gauges are renowned for their precision. They provide reliable readings that are essential for applications where even minor pressure variations can have significant consequences.

2. Durability: These gauges are built to withstand harsh environments. With no sensitive electronic components, they are resistant to shock, vibration, and extreme temperature conditions.

3. Instantaneous Readings: One of the greatest advantages of mechanical gauges is their real-time, at-a-glance readings. Operators can quickly assess pressure conditions without the need for complex interpretations or additional equipment.

4. Wide Range of Applications: Mechanical structured gauges are used in countless applications, from monitoring hydraulic systems and gas pressure in pipelines to measuring blood pressure in medical settings.

Applications of Mechanical Pressure Gauges

Mechanical structured gauges have found their place in various industries:

- Manufacturing: Ensuring precise control of pressure in industrial processes.

- Energy Production: Monitoring pressure in power plants, oil and gas facilities, and renewable energy installations.

- Healthcare: Measuring blood pressure and other medical applications.

- HVAC Systems: Maintaining and regulating air and water pressure in heating, ventilation, and air conditioning systems.

Choosing the Right Mechanical Pressure Gauge

Selecting the right needle pressure gauge for your application is crucial. Consider factors such as the pressure range, connection type, and the medium being measured. At [Your Company Name], we offer a wide range of mechanical pressure gauges designed to meet various needs. Our team of experts is ready to assist you in finding the perfect gauge for your specific application.

In conclusion, mechanical pressure gauges continue to be a cornerstone of pressure measurement across industries due to their reliability, precision, and durability. If you have any questions or need guidance in selecting the ideal needle type pressure gauge for your requirements, please don't hesitate to contact us at sales@wesen-tech.com.

WESEN Technologies - Your Trusted Source for Precision Pressure Measurement Solutions.