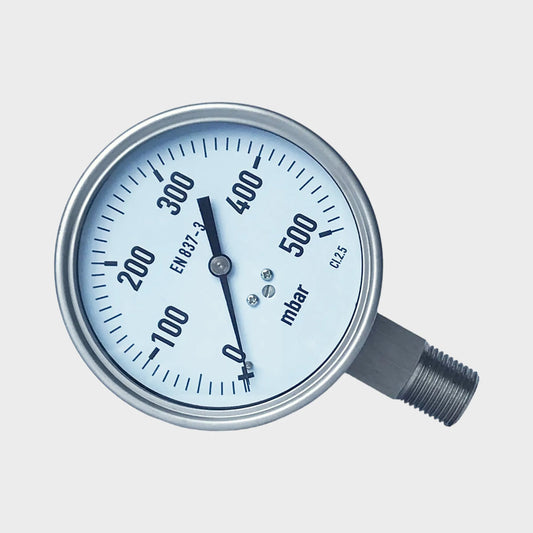

A bellows pressure gauge is a type of pressure measuring instrument that uses a bellows-like expansion and contraction mechanism to measure the pressure of gases or liquids. The bellows, which is a flexible metal element, responds to changes in pressure by expanding or contracting. This movement is then mechanically translated into a pressure reading displayed on a dial. Bellows pressure gauges are often used in applications where high sensitivity and accuracy are required, such as laboratory settings or applications involving low pressure measurements.

Here's a breakdown of the key features and functioning of bellows pressure gauges:

1. Bellows Mechanism:

The central feature of a bellows pressure gauge is the bellows itself. The bellows is a cylindrical, accordion-like structure made of thin, flexible metal. When pressure is applied to the inside of the bellows, it expands, and when pressure decreases, it contracts. This expansion and contraction movement is directly proportional to the pressure changes within the system being measured.

2. Working Principle:

The working principle of a bellows pressure gauge is based on the expansion and contraction of the bellows due to pressure changes. The bellows is connected to a movement mechanism that translates its movement into the rotation of a pointer on a dial. As the bellows expands or contracts in response to pressure variations, the pointer moves along the dial, indicating the pressure reading.

3. Components:

A bellows pressure gauge consists of the following components:

- Bellows: The flexible metal component that expands and contracts with changes in pressure.

- Connector: The point where the pressure being measured is applied to the inside of the bellows.

- Movement Mechanism: Converts the linear motion of the bellows into rotational motion of the pointer.

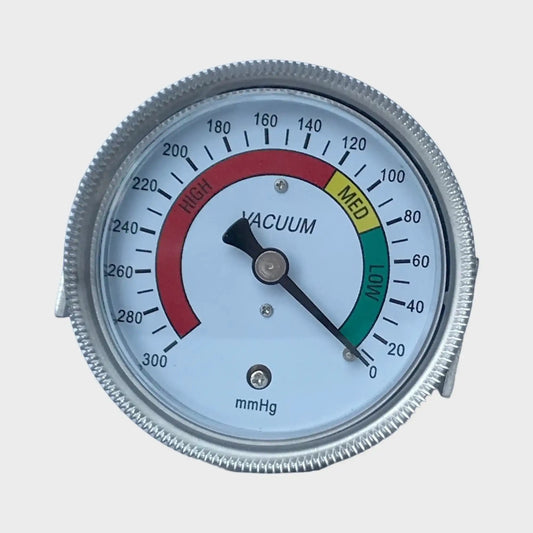

- Dial: Displays the pressure reading, usually calibrated in units such as psi or bar.

- Pointer: Indicates the pressure value on the dial.

- Cover: Protects the dial and pointer from damage and environmental factors.

4. Applications:

Bellows pressure gauges are used in applications where high sensitivity and accuracy are required. Some common applications include:

- Laboratory Settings: Measuring precise pressures in scientific experiments and research.

- Low-Pressure Applications: Monitoring very low pressures, such as in vacuum systems or specialized manufacturing processes.

- Analytical Instruments: Gauges used in instruments that require accurate pressure control, like gas chromatographs.

5. Advantages and Considerations:

- High Sensitivity: Bellows pressure gauges are known for their high sensitivity to pressure changes, making them suitable for low-pressure measurements.

- Accuracy: They can provide accurate readings for applications requiring precise pressure control.

- Specialized Applications: Their sensitivity makes them ideal for applications where other pressure gauges might not provide accurate results.

- Maintenance: Bellows pressure gauges can be delicate and require careful handling to avoid damage to the bellows.

6. Digital and Electronic Alternatives:

While bellows manometers are accurate and sensitive, digital and electronic pressure sensors have gained popularity due to their ease of use, remote monitoring capabilities, and integration with automation systems. These digital alternatives provide accurate readings and can cover a wider range of pressures.

In summary, a bellows pressure gauge uses the expansion and contraction of a flexible metal bellows to measure pressure changes. It's particularly useful for applications requiring high sensitivity and accuracy in low-pressure measurements.