WESEN TECHNOLOGIES

Pressure gauge manufacturer in China. Undertake customized orders.

Recommended Products

-

SF6 Gas Density Monitor For SF6 Gas Insulated Switchgear (GIS)

Regular price $249.00 USDRegular priceUnit price per -

Bimetallic Thermometer Every Angle Mount Stainless Steel 120 C

Regular price $13.99 USDRegular priceUnit price per -

30 ATM Pressure Gauge For Medical Balloon Inflation Device

Regular price $1.99 USDRegular priceUnit price per -

63mm Stainless Steel Pressure Gauge Well Pump Application 12 Bar

Regular price $3.20 USDRegular priceUnit price per -

Manometer For Gas Pressure 150mm Stainless Steel Pressure Gauge 300 PSI

Regular price $9.98 USDRegular priceUnit price per -

30 ATM Balloon Inflation Device Medical Pressure Gauge 40mm

Regular price $1.59 USDRegular priceUnit price per$1.99 USDSale price $1.59 USDSale -

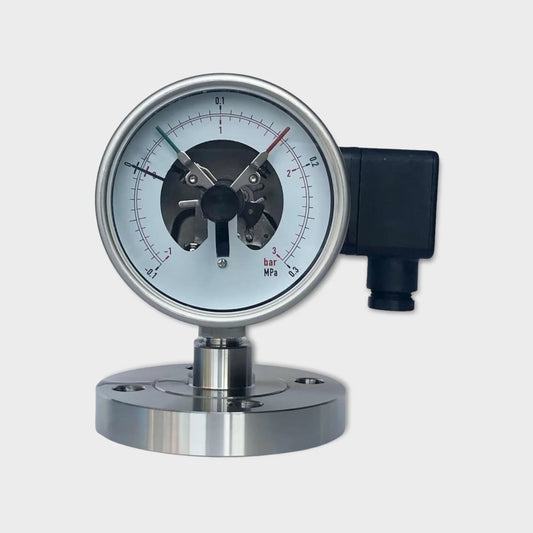

63mm Dial Diaphragm Seal Pressure Gauge Flange Mount Contact Gauge

Regular price $75.58 USDRegular priceUnit price per -

100mm Vacuum Pressure Gauge Lower Mount -30 to 0 inHg

Regular price $16.49 USDRegular priceUnit price per -

63mm Capsule Pressure Gauge Zero Adjustment U Clamp Mount

Regular price $4.29 USDRegular priceUnit price per -

100mm Dial Gas Manometer Lower Mount with Range 0 to 1 MPa

Regular price $3.29 USDRegular priceUnit price per -

100 Psi Stainless Steel Pressure Gauge with U-Clamp Bracket

Regular price $1.69 USDRegular priceUnit price per -

15000 Psi Hydraulic Pressure Gauge with Glycerine Filled

Regular price $3.80 USDRegular priceUnit price per

New Products

Digital Pressure Gauge

Digital pressure gauge is a new type of intelligent and multi-functional measuring...

D200 Series Digital Pressure Gauge

CNG Pressure Gauge

CNG automobile gas pressure gauge (sensor) is a very important part of...

-

Technical Competence

Reliable technical team to satisfy customer needs and solve problems.

-

Quality Control

Adapt high accuracy equipments, follows strict testing & quality control procedures.

-

Service Capability

Well-trained sales & service team to provide high quality end-to-end service.

What is a pressure gauge?

A pressure gauge is a device that measures the pressure of a gas or liquid within a system. It typically consists of a dial or digital display connected to a sensor that measures the pressure of the substance, and a mechanism for displaying the measured pressure. Pressure gauges are commonly used in a variety of applications, including in air compressors, boilers, and automotive and aircraft systems, to monitor and control the pressure of gases and liquids. They are also commonly used in industrial, scientific, and medical settings to measure and control the pressure of various substances.

Which pressures do pressure gauges measure?

Pressure gauges are instruments that are used to measure the pressure of a fluid or gas within a system. They work by measuring the force that the fluid or gas exerts on a surface, and displaying this measurement in a convenient and easily readable form, such as on a dial or digital display.

There are several different types of pressure gauges that can be used to measure a variety of different pressures, including:

Gauge pressure: This is the pressure above or below atmospheric pressure.

Absolute pressure: This is the total pressure of a fluid or gas, including atmospheric pressure.

Vacuum pressure: This is the pressure below atmospheric pressure.

Differential pressure: This is the difference in pressure between two points in a system.

Hydrostatic pressure: This is the pressure of a fluid at rest, caused by the weight of the fluid.

Stagnation pressure: This is the pressure of a fluid in a system that is not flowing.

Impact pressure: This is the pressure of a fluid when it is moving at a high velocity.

Dynamic pressure: This is the pressure of a fluid when it is flowing through a system.

Static pressure: This is the pressure of a fluid when it is at rest.

Pressure gauges can be used to measure the pressure of a variety of fluids and gases, including water, oil, air, and other gases. They are commonly used in a variety of applications, including automotive, industrial, and laboratory settings.

How does a pressure gauge work?

A pressure gauge works by measuring the pressure of a fluid or gas within a system and displaying this measurement in a convenient and easily readable form. There are several different types of pressure gauges, but most operate on the same basic principle.

The heart of a pressure gauge is a flexible diaphragm or Bourdon tube that is connected to the system being measured. When the fluid or gas in the system exerts pressure on the diaphragm or Bourdon tube, it causes it to deform. This deformation is transferred to a mechanical linkage, which in turn moves a pointer on a dial or displays a digital reading.

The movement of the pointer or digital reading is proportional to the pressure being measured. The scale on the dial or display is calibrated to show the pressure in a specific unit of measurement, such as pounds per square inch (psi), bar, or kilopascal (kPa).

There are several different types of pressure gauges that use different methods to measure pressure, including mechanical gauges, electronic gauges, and digital gauges. Some pressure gauges also include additional features, such as alarms or transmitters, to help monitor and control the pressure within a system.

What material should my pressure gauge be made of?

The material that a pressure gauge is made of is important because it determines the gauge's durability, accuracy, and overall performance. The best material for a pressure gauge will depend on the specific application and the type of fluid or gas being measured.

Here are some common materials used in the construction of pressure gauges:

Stainless steel: This is a common material for pressure gauges because it is strong, corrosion-resistant, and has good temperature resistance. Stainless steel is often used in harsh environments or for measuring corrosive fluids.

Brass: This is a strong and durable material that is commonly used in pressure gauges. It is resistant to corrosion and has good temperature resistance.

Plastic: Some pressure gauges are made of plastic, which is a lightweight and inexpensive material. Plastic pressure gauges are not as durable as those made of metal, and are not suitable for use in high-pressure or high-temperature applications.

It is important to select a pressure gauge that is made of a material that is compatible with the fluid or gas being measured, as well as the specific operating conditions of the application. For example, a pressure gauge used to measure the pressure of a corrosive fluid should be made of a corrosion-resistant material, such as stainless steel. Similarly, a pressure gauge used in a high-temperature environment should be made of a material with good temperature resistance, such as brass or stainless steel.